Articles

Everything You Should Know About Quick Couplers

The first thing to consider is that the connection must be solid! Ask yourself the question, when the connection is, for example, subject to strong or constant vibrations will it be secure? A repetitive vibration can cause an accidental disconnection that will cause a very dangerous hose whip! At 90 PSI, during the hose whip, the “live” end is over 100 mph (160 km/h)! Be especially careful with couplers installed on hoses that are dragged on the floor. Friction, pulling, or crushing can cause accidental disconnection. In this context, choose couplers with a "button" (or pressure) release system over those with a ring-type release system. A hose extension, using a quick coupler with a button-type release system will not risk releasing when dragged, avoiding a dangerous accidental disconnection.

Compressed Air Hazards: How to Minimize Hose Whips

In my last blog we focused on due diligence in occupational risk and safety prevention and the importance of doing a morning check routine. In this blog, we will focus on a real case in the industry and make recommendations on products and installations, so that we can avoid dangerous incidents.

Preparing the Air at Point of Application

If there is a vast subject to be explored in the field of compressed air, it is that of air preparation. Whether we are talking about air preparation, treatment, or conditioning, we are always talking about the same thing. Whether it is pollution, humidity, or approximate pressure, air should not be used in the raw state (directly from the compressor). In order to work well, and I’m talking about both the efficiency of the tool and the quality of the desired result, you have to “treat” the air to be able to exploit it as a reliable and viable energy source. To do so, we will look at three major aspects:

How to Choose an Industrial Air Compressor

Throughout my career, I have assisted many people who wanted to review their entire compressed air system. The first thing to do is a complete inspection of the system, starting with the compressor room. This leads me to want to share with you today my knowledge of a key component of the system: the compressor. Specifically, I will discuss two topics related to stationary compressors, which are often used in companies.

Why and How to Dry Compressed Air

Many of us have to use dry air in our professional activities. Everyone is more or less familiar with the damage caused by just a few water particles in the air... And I am not just talking here about auto body painters, but in a very broad way, about all the applications subject to the use of machines prohibiting any trace of moisture in compressed air. This is the case with welding, laser cutting, "clean room" installations, etc.

Health and Safety Solutions for Compressed Air

Accidents caused by improper use of compressed air are common. Safe and appropriate use of products for compressed air reduces the risk of injury and improves overall productivity. We have grouped our security solutions according to the problem to which they relate. Take stock of your solutions and consult our Safety Solutions Catalogue to complete your compressed air system.

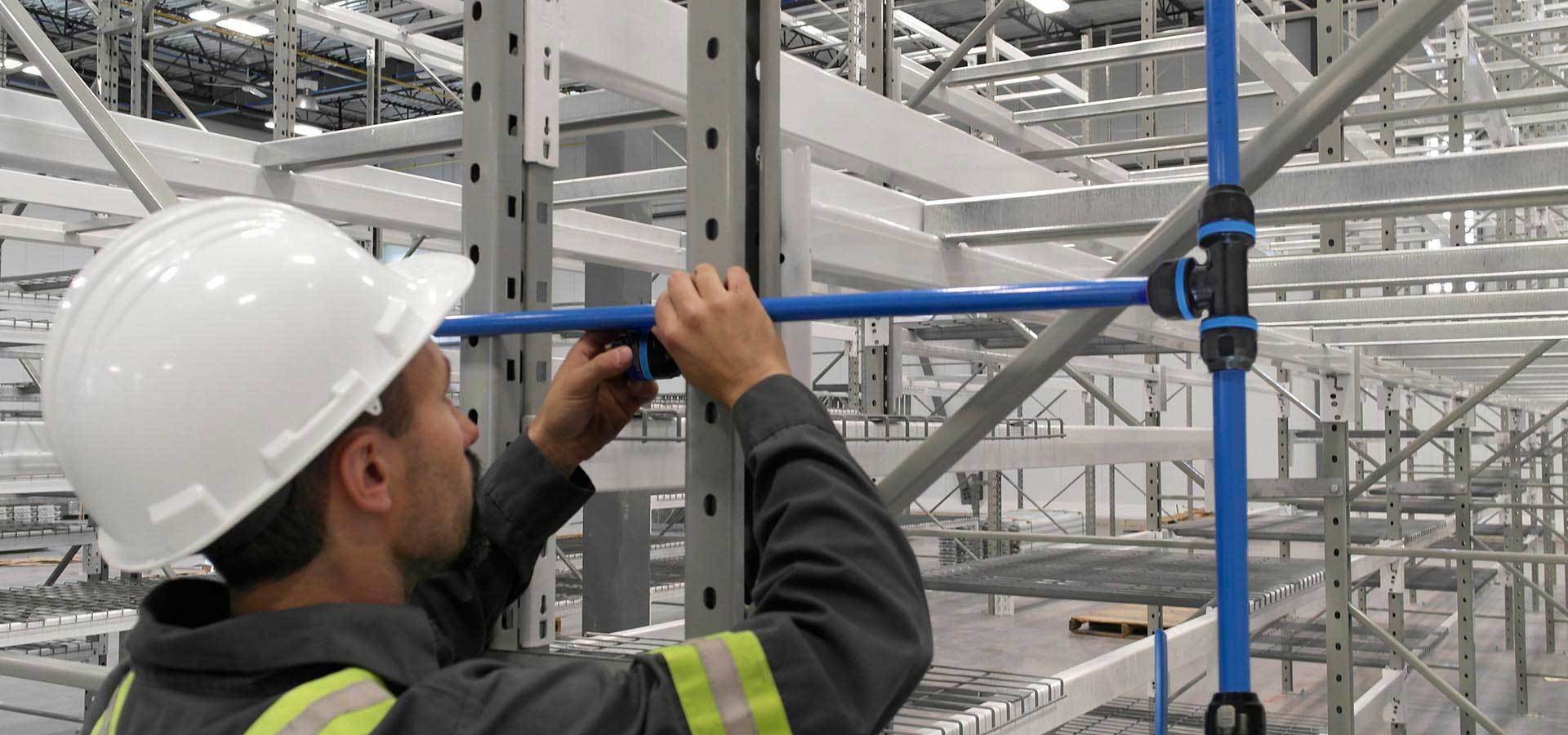

The Secret to a Perfect Compressed Air System

For years you've been promising yourself to redesign your air network, to start completely from scratch. Yet you keep postponing the project maybe for... lack of time, resources, and/or knowledge... all excuses are okay! However, a few simple rules of thumb are enough. And once the work is done, you'll wonder why you didn't do it sooner. To help you, I have compiled a list of key elements to respect for an optimal network. You'll see, it's really very simple!

How To Adjust the Spring Tension of a Hose Reel

The tension on a hose reel spring is typically adjusted in the factory, but over time, the spring may lose or gain tension.

How Does a Cyclonic Water Separator Work?

When we talk about the elements that make up the compressor room, we immediately and rightly so, mention the compressor(s), the tank, the dryer, and finally the filtration units... But there is one element that is often forgotten as it is so discreet… The cyclonic water separator! I would even say that not only do we forget to mention it, but also too often, to install it!!! One could say that it is (alas) the great forgotten parts of the compressed air production system... So, let’s endeavor here to fill this gap by presenting and explaining who this unfortunate stranger is.

Installing a Compressed Air System in Your Workshop or Home Garage

To guide you in your planning, here are the elements to be expected before undertaking your compressed air system installation project in your workshop or home garage. Take the time to plan each step of the process and, if necessary, do not hesitate to call on a Topring expert to help you.